Principles of 5GDHC and KPIs

The 5 principles of 5GDHC

To ensure a flexible and resilient energy network to meet current and future needs, a 5th generation heating and cooling system (5GDHC) is established on the following five principles:

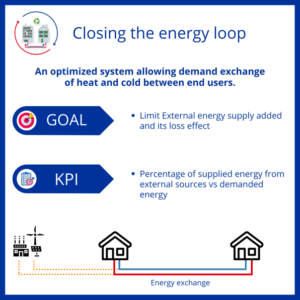

Closing the energy loop

Heated and cooled buildings will always lose energy, which must be compensated with external sources and/or between buildings (fulfilling cooling demand delivers heat to the DHC-system and fulfilling heating demand delivers cold to the DHC-system). The idea of the 1st principle is to prevent internal waste in the system, by reusing and closing energy loops as much as possible and by using energy storage for temporal imbalance. The key factor in the 5GDHC approach is the optimal re-use of the return flows at differing spatial and time scales. We work bottom up on this principle, by first exchanging within a building/complex, second on cluster/neighborhood level, and finally at city/district level. Further optimization will not be technical, but more so in spatial planning.

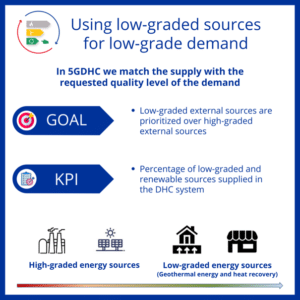

Using low-grade sources for low-grade demand

In the future, the amount of high-grade (high exergy) sources will be limited. Apart from meeting local demand with the large available flows of low–grade energy (like shallow geothermal, industrial waste flows, conversion waste, waste from cooling processes, sewage etc.), the unavoidable amount of additionally (high–grade) supply is best taken form green sources like deep geothermal, windmills, solar, hydropower, and biomass. This allows the system to fully phase out fossil fuels and regenerate its thermal energy from the low-grade thermal energy sources.

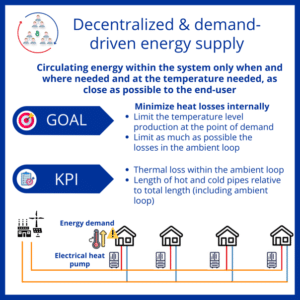

Decentralized & demand-driven energy supply

Many systems are centralized and demand-controlled, for example in monitoring the return flows of energy. Those systems circulate a lot of energy which is never used. So, this principle’s aim is to work bottom-up, and to start generating and circulating energy only if a demand occurs. This focuses on enabling the ability to simultaneously deliver heating and cooling services at different temperatures to different customers, exactly as demanded, when demanded, and never more than needed.

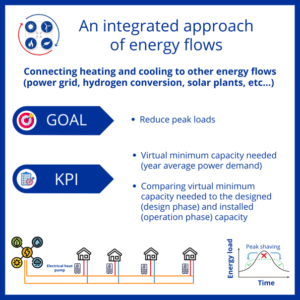

An integrated approach of energy flows

Many energy systems contain split incentives, which means that they do not optimize on the integral need across systems and sectors. Integration is not only important for saving energy, but also for reduced investments in capacities, like managing peak loads. The aim of this principle is to develop a 5GDHC system to be integrated with all other energy flows in a given area (power grid, transport, industry, agriculture, etc.) to maximize optimum efficiency of energy delivery and use.

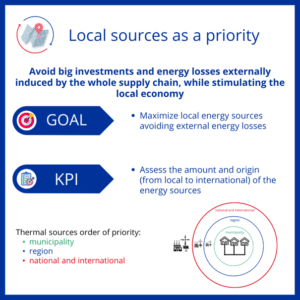

Local sources as a priority

Often, plans are made on large scale and considering big plans with distant energy sources. The business case is not always integral, so some costs are for end-users and others seen as societal costs. The aim of this principle is what you can get locally should be prioritized above more distant sources, to save on transport losses and investments.

What is a KPI and

why is it required?

© Mijnwater B.V, Heerlen & Pascal Moors

KPIs to assess the 5 principles

KPI stands for key performance indicator, a quantifiable measure of performance over time for a specific objective.

5GDHC is not only a theoritical concept, it finds concrete applications through network projects in several countries. As a result, it is necessary to verify how well these projets meet the objectives of the 5 principles.

One of the main takeaways of the D2GRIDS project will be thus the confrontation between the principles and the reality of projects, leading to a value scale for each KPI.

Each principle can be assessed by a set of KPIs

This set of KPIs allows to compare different projects in term of achievment of the 5 principles of 5GDHC.

KPI 1: Maximizing the internal exchange of energy and self-sufficiency

The KPIs inspired from the 1st principle are meant to assess the amount of energy exchanged within the system.

KPI 2: Increasing the share of low-graded sources for low-graded demand

This KPI aims to assess how much of the energy supplied to the system is low-graded.

KPI 3: Adapting the network's architecture to the end-user demand

Because the energy required by the end user should be produced only when and where needed, this KPI assesses the decentralized aspect of the network.

KPI 4: Reducing peak loads and downsizing production facilities

One way to reflect the fourth principle is to verify through a KPI how oversized the DHC installed capacity is. A well sized DHC system reflects that the storage has been optimized, that the peak loads have been reduced and that the investment has been minimized.

KPI 5: Prioritizing local energy sources

This KPI evaluates how far the energy used by the network come from.