Bochum

Germany

Drilling Platform

Drilling Platform

Energy center east

Energy center east

Mark 51 overview

Mark 51 overview

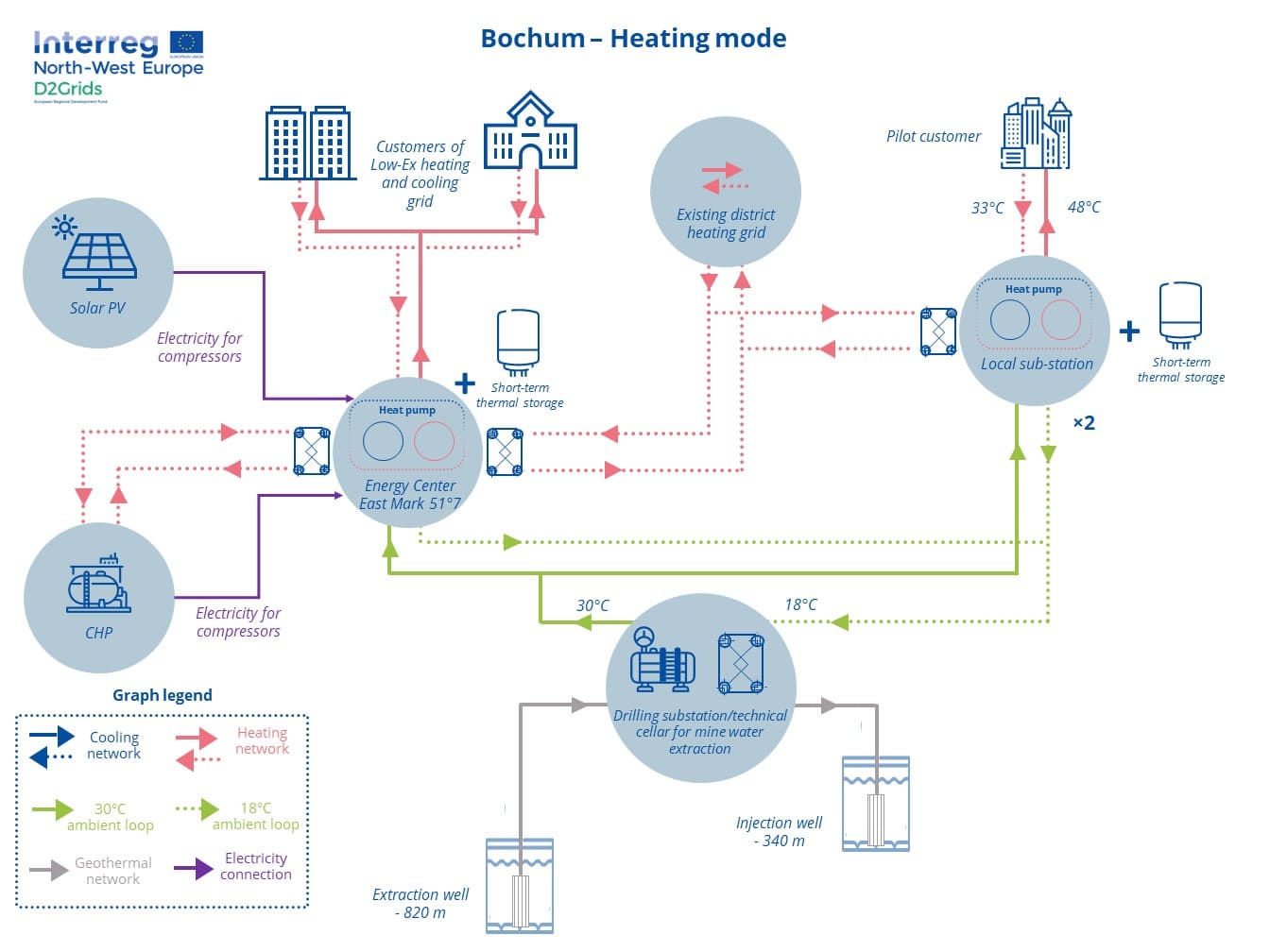

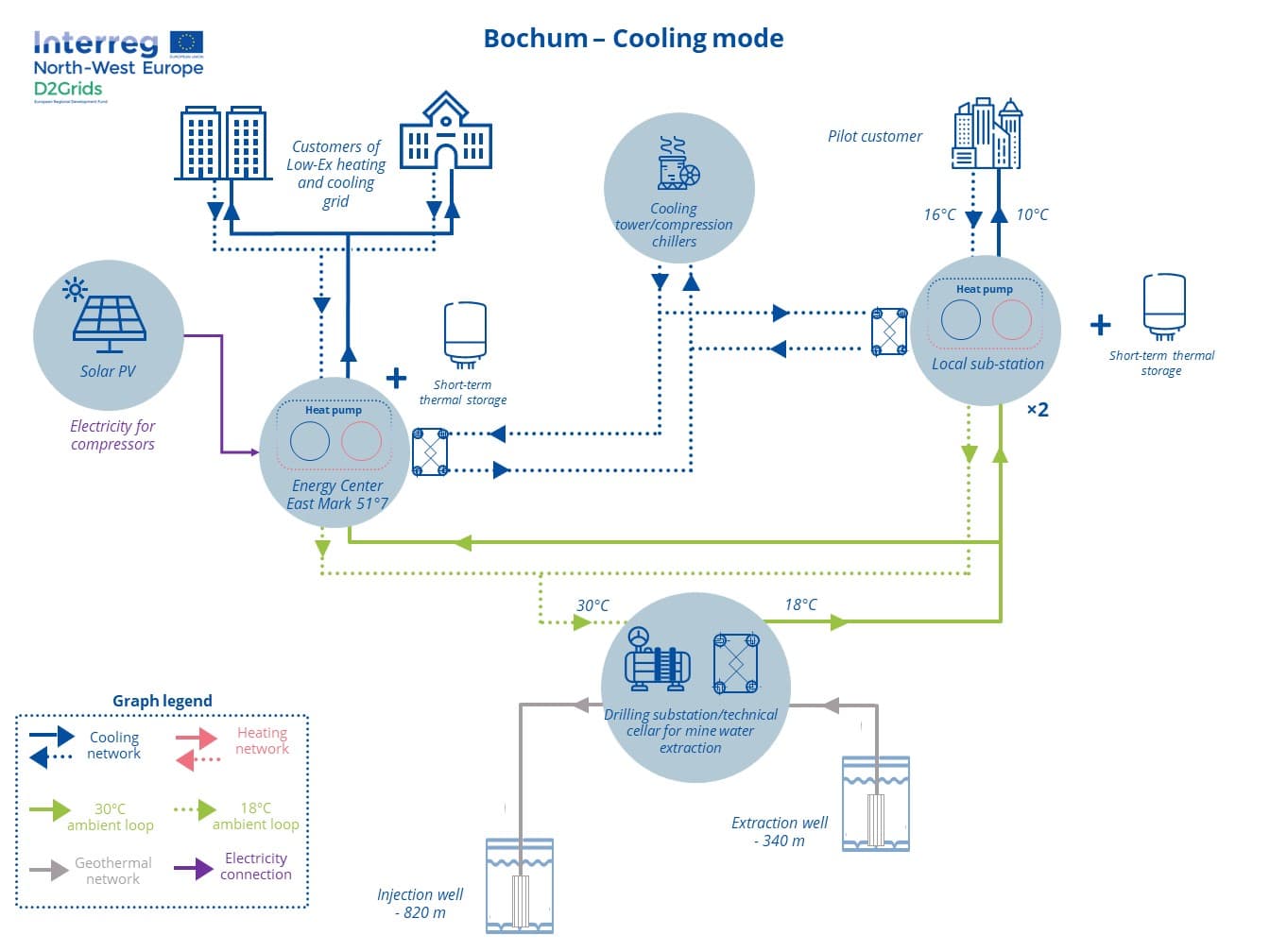

FUW GmbH (in cooperation with Stadtwerke Bochum Holding GmbH) intends to set up an innovative, highly efficient and environmentally friendly 5th generation heating and cooling supply on the « Mark 51°7 » site. The “Mark 51°7” site is located in Bochum Laer. It is the area of the former plant of the automobile manufacturer Opel with a total area of 68 ha. After the end of automobile production in 2014, the area is available for subsequent use. In the north-western area of “Mark 51°7” is the former “Dannenbaum” coal mine, which was in operation until 1958. An essential part of the energy supply concept on “Mark 51°7” is the use of mine water as a heat source to cover a large part of the heating and cooling demand of the customers located on the site. For this purpose, the geothermal heat and cold stored in the mine water of the former « Dannenbaum » coal mine is used.

The heat and cold from the two geothermal wells is coupled out to an intermediate circuit via heat exchangers and transported mainly to the so-called “Energy Center East” (EZO) (supply of 23 customers) as well as two smaller decentral heating and cooling centers (same design as EZO), each for one customer. Within the “Energy Center East”, a heat pump system raises the temperature level of the mine water for the downstream low-temperature heating grid and lowers it for the downstream cooling grid. The consumers connected to these two grids receive heat for space heating and cold for space cooling. Since mainly office buildings will be built in this area of the site, the respective temperature levels are sufficient. The heat pump system is designed for the base load supply. The peak load for heat supply is provided via the upstream 3rd generation district heating grid, while the peak load for cold supply is generated by compression chillers, which are also located in/on the “Energy Center East”.

Total surface served

196 000 m²

Amount of connections

25

Type of consumers

Business

Heat sources

Geothermal well + heatpumps + CHP + District heating network

Cooling sources

Geothermal well + chillers

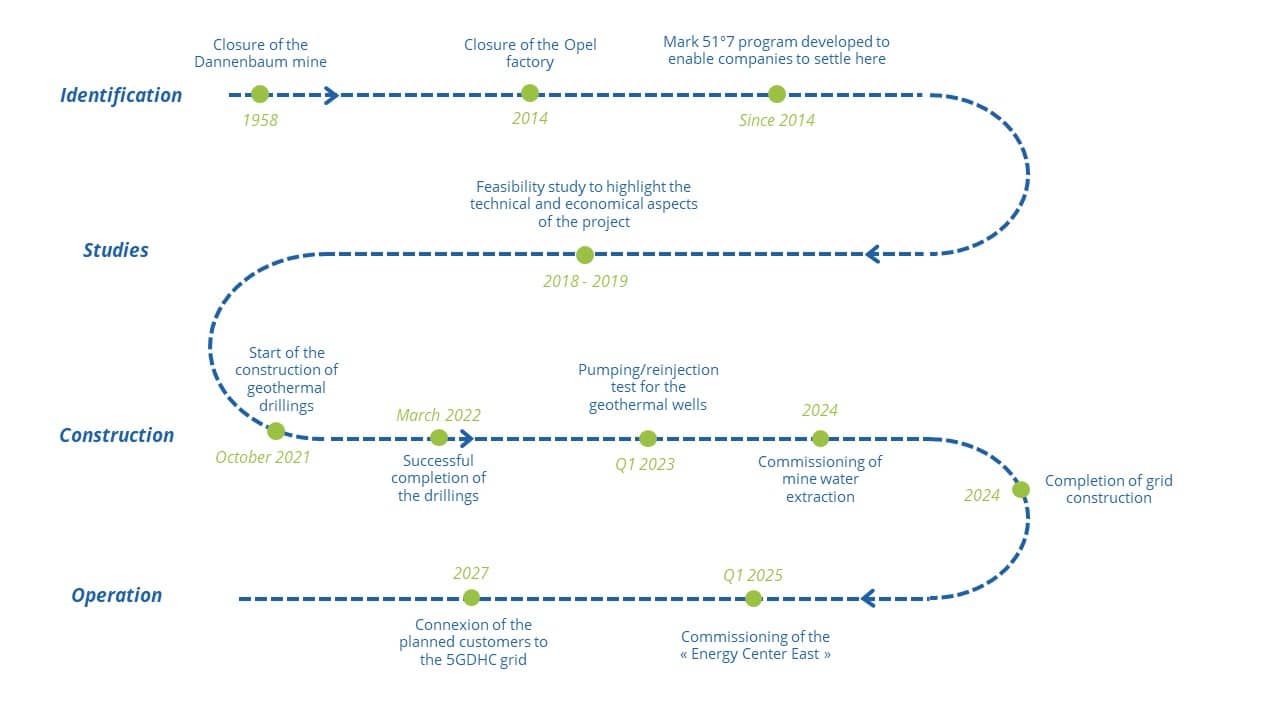

Timeline

Blueprints and technical datas

Length of Network

5 850 m

Heating Capacity

12 MW

Annual Heating Demand

16 GWh

Cooling Capacity

10 MW

Annual Cooling Demand

10 GWh

5GDHC Principles

Demand driven and bidirectional at the points of delivery

The pilot customer Faiveley is connected to the thermal mine water network via a substation with a local heat pump. This thermal network will be expanded later, with further substations (heating and cooling centre with heat pumps) to follow. The network is set up in such a way that the heating and cooling capacities can be made available to different customers at different temperatures.

Closed energy loops

The network will be set up in such a way that it will be possible to exchange heat and cold requirements between customers in the future expansion with several substations and connected secondary subnetworks. The net flows are balanced by short-term decentralized storage of the substations and by the heat source and low-grade thermal source of the mine water reservoir. The latter also serves as long-term (seasonal) centralized large-scale storage.

Low grade thermal energy sources

The low-grade thermal source of the mine water reservoir covers a large part of the heating and cooling requirements. Short-term peaks in demand are partially offset by short-term decentralized storage.

For more information,

please visit the project website